Services

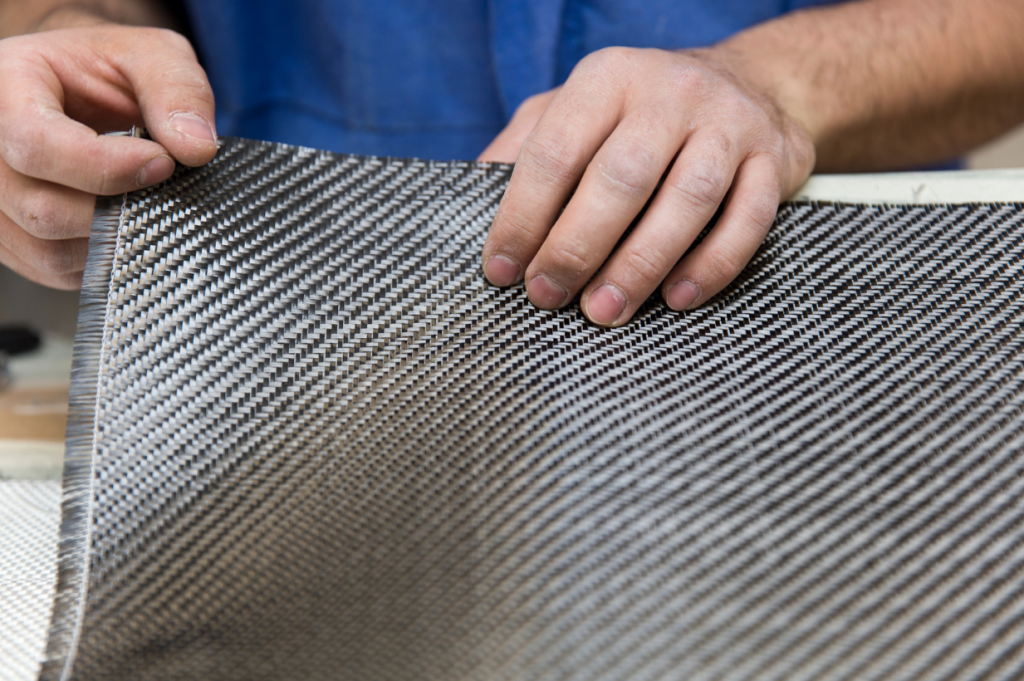

Leading the manufacturing of carbon fiber composite components

Each of our services, from prototyping to the production of carbon fiber composite components, reflects our steadfast commitment to quality and innovation in every phase of the process.

Product Development

Product Development

Prototypes

Prototypes

Mold and Tooling Design

Mold and Tooling Design

Production of Composite Components:

Production of Composite Components:

Mold and Tool Manufacturing:

Mold and Tool Manufacturing:

Machining and Subassemblies:

Machining and Subassemblies:

A comprehensive approach

The phases of all our processes are transparent and clear.

We start with technical advice: conducting feasibility studies, defining specifications, and exploring mechanical solutions. We support innovation by exchanging ideas and exploring cutting-edge concepts.

In the design stage, we create detailed CAD models, virtually validate, and establish the phases of process engineering. During manufacturing, we use technologies such as manual layup, filament winding, and RTM to build prototypes and carry out mass production, if necessary.

In the testing stage, we validate the quality and performance of each piece. We use specialized instrumentation for precise measurements and evaluations. This rigorous testing allows us to deliver products that consistently meet the highest levels of quality and performance.

State-of-the-Art Facilities

Our facilities provide the perfect environment for working with composite materials. Each space has been carefully planned to cover all phases of the production process. The creation of exceptional parts begins here.

Autoclave 2400x6000, 6bar, 180oC

Autoclave 2450x4500, 10 bar, 250oC

Cuttingplotter

2 Freezer for Raw materia

Oven 3000x3000x2000, 250o

Sandblasting machine

Cutting cell

ABB 6700 Robot for trimming

Precision, efficiency and careful attention to detail

We are here for you!

Let’s talk. Fill out the form, and we will get back to you as soon as possible. Thank you for your interest.